Click all framed photos to enlarge.

|

|

|

| Hull mold. |

Smooth underside for installing air dams or

tunnels to the mold later. |

Deck formed. Test fit of outer hull to outer

deck. |

|

|

|

| Hull formed. |

Black urethane sealant used to bond the hull. |

Seam at rear of sponsons. |

|

|

|

| Seam at transom. |

Starboard Stringer (Concept) Production

stringers may be aluminum 1/8" x 3/32" member bar joists with

the same geometry as the black lines on this PVC prototype. |

Port Stringer (Concept) Pre-cut and

Pre-drilled micro servo mount on one side. Receiver opening on other side.

Space between stringers

will be approximately 4-1/16 inches. |

|

|

|

| Locating gear for Liner design. N-2

Sport Hydro. Was able to obtain a proper CG. |

Really gets your imagination going! Not

practical to build this one as the hull has no reinforcing liner

installed. Looks pretty but its just not ready yet. |

Was able to get the CG in Limited Sport Hydro

as well. For those who want a 1/4" right offset drive, the ply motor

mount base can be easily modified to shift the motor without modifying the

hull. |

|

|

|

| Tunnel set in place on the hull mold. This last

detail makes it faithful to the original design and build. |

However, it can be removed to

experiment with other designs and configurations.

(Later, prototype testing and designer

consulting determined that the tunnel could be omitted without affecting

performance.) |

Rough hull liner mold. Still have to mill

the bed for the graphite bow- cross member. |

|

|

|

| Trays for motor mount & flex/straight

drive hull penetration. |

Truss mounting grooves in the hull

floor. |

Deck Reinforcement mold in-progress.

Double grooves will secure the rear sponson side bulkheads. |

|

|

|

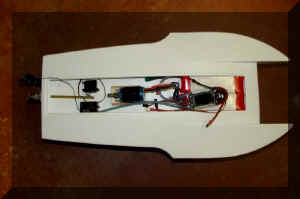

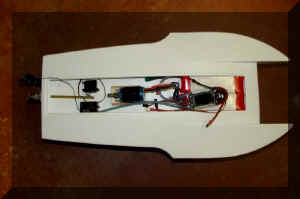

| Note the necessary internal structure is

minimal due to the reinforcing liners to the hull and deck. |

First look at the prototype stringers. They butt

against a large carbon-fiber spar at the bow, a PVC transom reinforcement at the

stern, and PVC sponson baffles. |

First Prototype Completed. Doug is

installing equipment. |

|

|

|

| No hatch cover yet. Need motor-clearance

measurements from Doug to design it. |

Nice lines. |

Rock-Solid deck. |

|

|

|

| Port stringer has mount for mini-servo. |

Starboard stringer has hole for

receiver. |

Maiden voyage of first prototype to

confirm a working setup. Unsharpened and unpainted hull. No tunnel. LSH

setup. 1 MB Video. |

|

|

|

| Going in circles. 1.3 MB Video. Recommend

you sharpen & paint before testing. In the water, unpainted styrene

drags more than painted styrene. |

1/6 mile oval at 33 mph. 3.5 MB Video.

Amp-Draw of the motor tests less with a painted hull. |

Oval with hull tunnel attached. 3.6 MB

Video. |

|

|

|

| Oval without tunnel attached. 1.7 MB

Video. |

8XL Brushless Setup. 1.7 MB Video. Not a

P-Sport boat. Just playing... |

8XL at 51 mph. 1.6 MB Video. |

| |

|

|

|

With our revolutionary Collision-Damage-Resistant

Vac-U-SeamTM Technology.

A new boat needs a new Logo. Meet our

Spokes-Pickle. |

| |

|

|

| Using hand-cut wood

and PVC reinforcements, several prototypes were produced for testing.

Due to their popularity, several more were required. |

| |

|

|

| |

|

|

| The hatch cover design is

temporary. It was the last-minute effort to cover the large hole in the

top of the deck in time for the Chattanooga Invitational. |

|

|

|

|

Prototype racing in Chattanooga 2007. |

|

|

|

|

| Chris's |

Doug's |

Rick's |

|

|

|

| John's |

Chris's w/ lighter LiPoly Batteries to

compare water-line. |

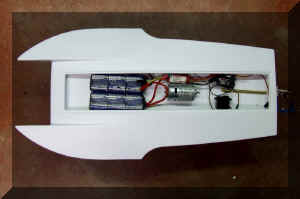

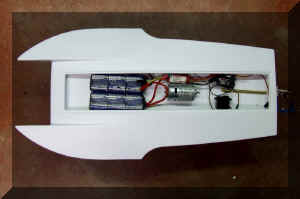

NiMh batteries close to motor. |

|

|

|

| LiPoly batteries farther forward |

Same here. |

Typical LSH Hardware Setup. Motor and

bracket are removable from the ply base plate. |

|

|

|

| Motor looks high but is on a low-profile

mount at 15 degrees down. |

A few friendly racing pics |

to show the ride of the kit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

June 17, 2007 Chattanooga Invitational. Vac-U-Pickle hulls

placed 1st, 2nd, & 3rd in first race. Placed 1st & 2nd in the second

race.

|

| |

|

|

| Final drawings were

transferred to CAD to produce laser-cut ribs, transom reinforcement, and

sponson baffles from hot-pressed mahagony plywood. A product that can be

boiled for 3 hours and still pass a shear-test for strength. Pulltruded

carbon-fiber rod was the best support for the front of the sponsons. |

| |

|

|

|

|

|

| View toward bow and the Carbon Fiber Sponson Brace. |

View toward the stern and its 3/16" thick hot-pressed

mahogany reinforcement. |

Pre-drilled servo box in port rib. |

|

|

|

| Flotation visible inside the sponson. |

Rear sponson Reinforcement Baffle visible through the

starboard rib. |

Radio Receiver access opening in the starboard rib.

|

|

|

|

| Photo of the real Atlas taped to hull for review. |

Now, had to get to work to make one. |

Test-Form over the "Atlas" cowl mold. |

|

|

|

| Good fit. Additional designs will follow later. |

A perfect motor mount was needed. This was the

result. |

Took all of the building hardware and weighed it for

the float test. |

|

|

|

| In the water with a brushless XL 540 motor, 2 nicad

packs, and AA cells equal to the hardware and receiver pack's weight, as

heavy as it could be built with a total load of 49.1 ounces (Not

including the weight of the hull). |

Removing all air trapped in the sponsons, it slowly

sunk. |

Leaving trapped air in the sponsons, it floated, but

not enough. |

|

|

|

| Added two strips of foam to the after-planes. |

Successful test. Plenty of flotation in case the

worst happens. |

Final flotation configuration. |

| |

|

|

| Production Begins! |

TM

TM